- 5500 Campanile Dr.

San Diego, CA 92182-8220 - 619-594-0791

- [email protected]

Lightweight Polyurea Foam

A versatile polyurea foam made using a scalable manufacturing process mitigates impacts more effectively than heavier foams on the market.

Polyurea foams are useful for absorbing energy and lessening the severity of impact

loads in nearly any application. Most polyurea foams are classifiable as either open-cell

foams or closed-cell foams. Open-cell foams more effectively absorb high impacts,

while closed-cell foams better distribute loads over a wider area.

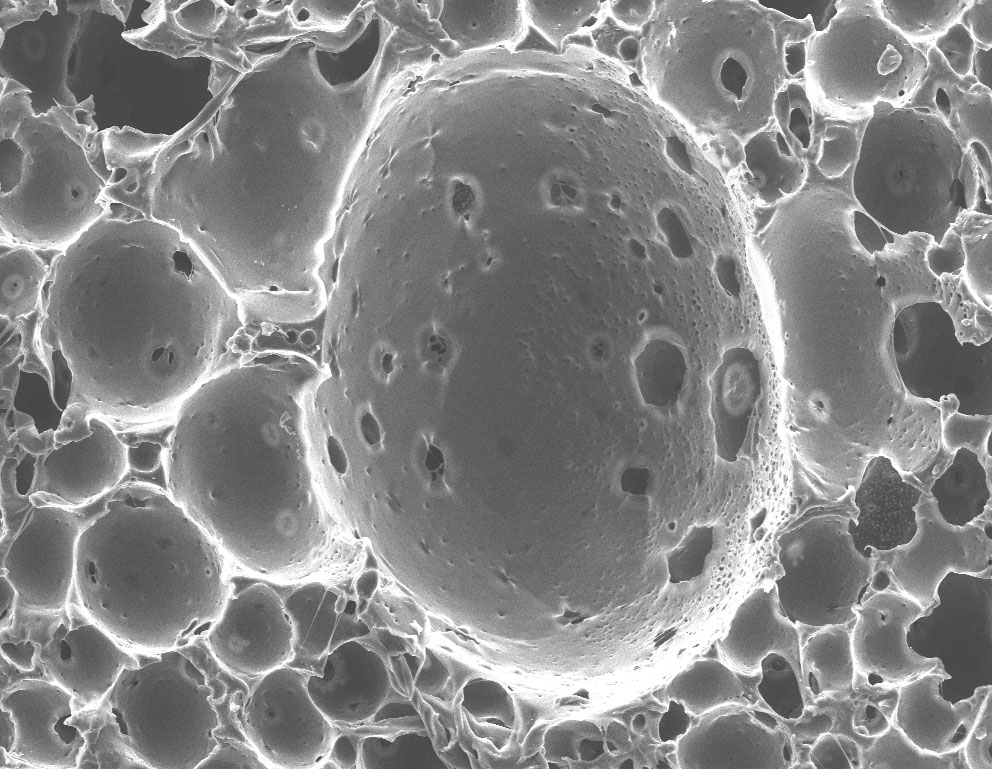

The invented polyurea foam has a novel "semi-closed cell" microstructure that inherits

the desirable mechanical and physical properties of both open- and closed-cell structures,

mitigating impact as good as or better than denser foams.

The polyurea foam is the result of an invented manufacturing process that eliminates

the need for a vacuum oven. In addition to greatly reducing the required energy, the

lack of a vacuum oven lessens the possibility of premature degradation and enables

more control over foam shape, thickness, and density.

Developed in part with funding from the DOD, industry can use the increased control to tailor the foam for any application.

In experiments, a prototype foam decelerated impacts more effectively than heavier competitors—one sample stored nearly double the energy (71.7 kJ/m3) of a commercially available foam despite being 12 percent lighter. The inventors continue to optimize the foam, nearing densities of 90 kg/m3.

Advantages

- Lightweight

- Net shape manufacturing

- Tailorable properties

- Energy efficient process

- Cost-savings at production scale

Benefits

- Military body armor (DOD-funded)

- Helmets

- Footwear

- Aerocraft

- Automotive exteriors

Lead Inventor

George Youssef, Ph.D.

IP Protection

• US 2020/0071483 (Pat. App. No. 16/118,879)

Recent Publication

• J. Applied Polymer Sci. 2020, 137, 48839